Vibratory bowl feeders with their high output, sword feeders with their gentle handling of coated screws, tape-on-reel feeders for the placement of self-adhesive components are some of the examples from the standard line of our feeding technology.

Our standard product assortment excels through the durable industrial quality and the high reliable. We only use high-alloyed and heat-treated steels for all critical components.

To assure the technically optimized and economic feeding of your components, DEPRAG carries out a comprehensive duration test that uses your components and simulates your production parameter, prior to delivery.

To determine the best suitable feeding technology for your application, our application experts gladly advise you in regards to the required technical specifications of your components to be transported.

This includes the feed criteria of your components to be transported, the advantage or disadvantage of the different feed principles, the selection of a single- or multiple feed process and the determination of fixtures or screwdriver-attachments that will fit your space conditions.

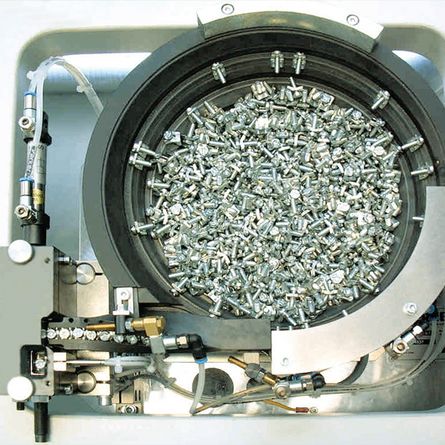

Vibratory Feeder eacy feed

Energy efficient and smart technology

The innovative feeder eacy feed provides ideal specifications for the sustainable production of tomorrow: With its approx. 80 % power saving accomplishment the eacy feed is extremely energy efficient. In addition, the smart eacy feed is particularly suitable for the challenges of smart factory/Industry 4.0

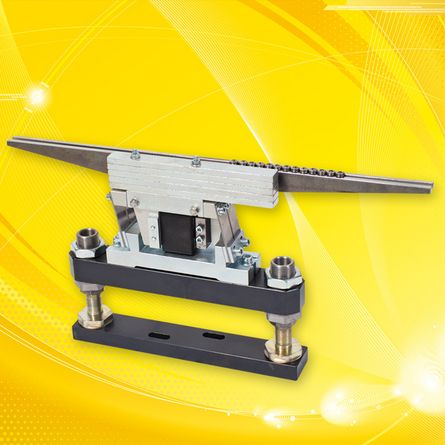

Sword (Segment) Feeder

Sword feeders or segment feeders are used when components are particularly sensitive and a heightened gentle feeding environment is required.

Screw Presenter and Screw Dispenser

Screw presenters are mainly used for applications where an automatic screwfeeding machine is not cost-effective due to low volume. A screw presenter can process screws with thread-sizes from M1 to M5 and a shaft-length of up to 25 mm.

Screw dispensers are optimised for use in manual work stations.

DEPRAG Feed Module – DFM

The DEPRAG Feed Module (DFM) enables screw assemblies on screw positions which are difficult to access, by using vacuum assistance.

Pick-and-Place Method

If the screw dimensions do not allow feeding through a feedhose, for example where there is an unfavorable relation between screw head diameter and overall length, we can offer special solutions, such as the Pick-and-Place process with vacuum suction or removal by gripper. This process can also be used if there are screw-locations that are difficult to access.

Linear Conveyor

Linear conveyors are often used to reduce distance of movement, to allow for parts buffer and to expand of the parts stream.

Our robust linear-conveyors assure the correct transport to the feedbowl without push-back-pressure. So, parts will never be backed-up while on the way to the feedbowl.

Step feeder system eacy step feed

The complete system, comprising a storage container, material-handling technology, linear conveyor, separator, housing and controller – specially designed for longer screws – offers hassle-free, reliable operation with 24V technology, independent from mains voltage and mains frequency.

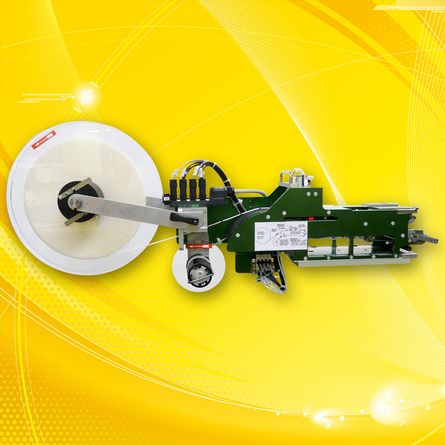

Tape-on-Reel Feeding

The DEPRAG Tape-on-Reel feeder is specifically designed for the process-reliable and position-accurate delivery of adhesive components, which are supplied on reel tapes. Electric components can be removed from a reel by the peel-off carriage and positioned accurately.

This easy to access system can be integrated directly into your assembly machine.

Storage Devices

We offer an assortment of storage devices that are the ideal addition to our feeding systems. Belt-driven hoppers dramatically increase the required refill intervals. Our hoppers are flexible devices that can be used for different parts – a costly refitting is not necessary.

Press-Insertion Systems

Pressurization systems consist of coordinated modules: the handheld pressurization device or the stationary press-module and the automatic feeder for the fasteners, such as rivets, pins and sleeves.

The efficient and process reliable pressurization and placement operations are done either by hand or by your assembly unit.

Individual Solutions

Besides the listed standard products, we also offer a variety of feed-systems that are specifically designed to fit your product and your assembly process. Our application experts will gladly advise you.