For reliable feeding machines a DIN quality standard (allowable 3% bad parts) is not always sufficient. Higher levels of screw/fastener quality improve the feeder`s reliability. The goal should be a quality grade of 10 ppm (“parts per million“). This means in every 100,000 screws there can be 1 bad part.

A vibratory spiral bowl is particularly suited to screws with awkward dimensions or those with special feed rate requirements. The sword feeder is applied when extremely gentle handling of the parts is required or when very low noise level is a must. If feeding with a hose system is not possible we also offer pick-and-place procedure.

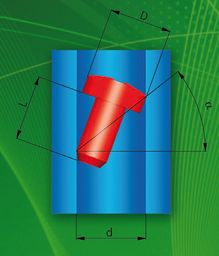

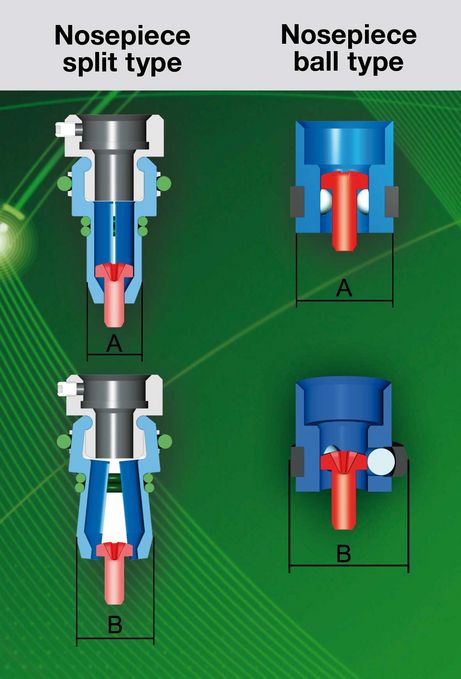

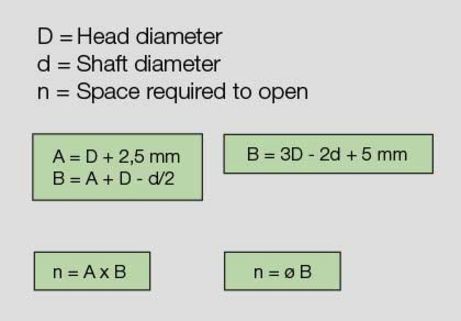

For effective use of the handheld screw feeders the space available around the screw head on the assembled components is very important.

There is a certain space requirement for the nosepiece split type and ball type.

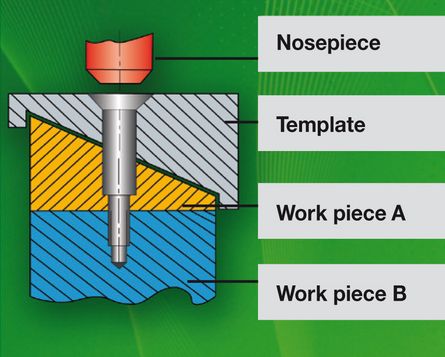

An even surface simplifies the positioning and handling of the tool. Slanted surfaces with small diameter recessed screw-holes can only be accessed with templates which are available as optional equipment.

For the correct layout of your screw feeding machine the following data is required:

- Voltage / frequency

- Choice of screwdriver model (torque and speed)

- Screw dimension and screw type (if possible please specify DIN no.)

- Torque (if known)

- Detailed dimensions of assembly components

- Hose length (if over the standard length of 2 m).

To process your order we require sample screws (approx. 1 feed bowl volume) and if possible some samples of the part to be assembled.

Do you need help?

Our application consultants are standing by to support you directly to define your specifications. Please contact us.