- Patented Vane-Exchange Feature

- Highly durable

- ATEX-compliant

- Short delivery times

- Flexible material options

Our powerful pneumatic motors offer interesting alternatives for drive- and control tasks for all industry areas. Click here to learn more about the functionality of a vane motor. DEPRAG also offers customized air motors for individual applications; those air motors are based on a modular construction system and a comprehensive standard catalog.

This modern and compact BASIC LINE air motor offers an especially attractive price-to-performance ratio due to his modular design and further advantages such as; high power density, small size, robustness, ATEX-certification for the use in explosion-proof areas.

When used in a dry environment and under standard stationary production operation, then the pneumatic motor made from cast-iron material is the best choice. Get advice from our engineers now.

This air motor series is available in 3 power classes:

200 W – 400 W – 600 W – 900 W – 1.2 kW

The pneumatic motor remains where it is installed. This feature is an enormous time saver.

Low Maintenance: After loosening the cap-screws and removing the rollers, the vanes may be removed using a tweezers. Afterwards the new vanes may be installed in reverse order.

All air motors can be operated oil-free, without special measures.

Additional information on the BASIC LINE air motor

ADVANCED LINE air motors

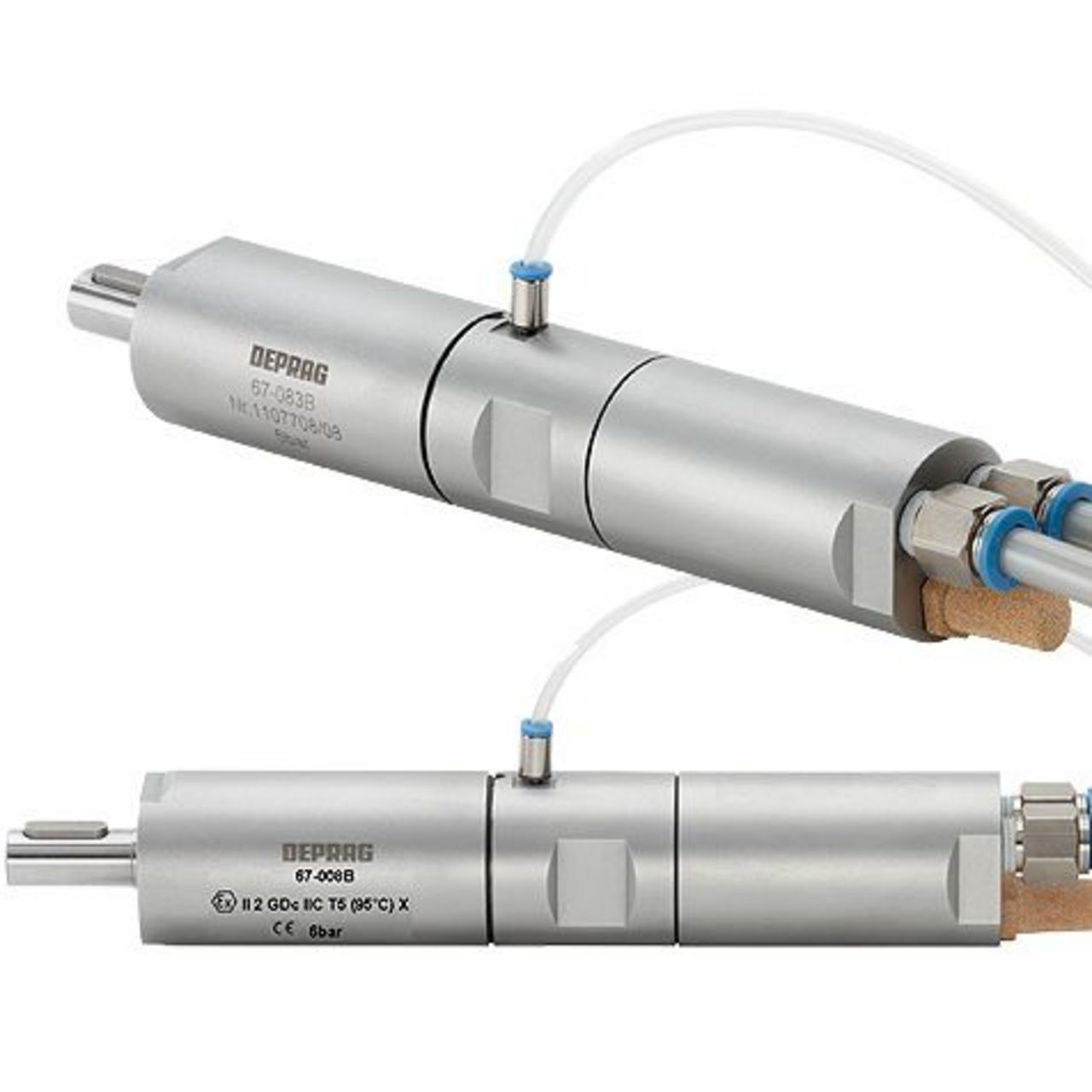

The ADVANCED LINE air motor made from stainless steel is used in areas where high hygiene requirements are necessary. This air motor is especially suited for the use in the food industry, medical industry, pharmaceutical industry and chemical industry, etc.

The ADVANCED LINE air motor is fully sealed and steam-resistant. It is even possible to operate this air motor under water (completely submerged).

All air motors are made from stainless steel and can also be used without lubrication with only a slight power loss of approx. 15%. Because of our flexible and modular system, we can offer a multitude of variation possibilities (for example differently designed drive spindles, etc.), at a very attractive cost-benefit ratio.

For the use in agitators or mixers, which have a very stringent hygiene requirement, we can offer our air motors with a high-torque gearing that is made from stainless steel as well.

Stainless steel air motor with integrated planetary gear

The vane motors of the ADVANCED LINE are especially compact drives for integration into handheld devices or industrial facilities. These high quality stainless steel motors are especially suitable for the Paper and Food Industries, for Chemical and Pharmaceutical Industries and also for application in Medical Technology. The ADVANCED LINE airmotor is fully sealed and can be operated without lubrication.

Available power classes:

20 W to 1.2 kW

High-torque air motor made from stainless steel

Our high torque air motors are stall-proof; for example the stall-torque of the motor 67X-517 is 800 Nm. This drive is especially well-suited for the use in industrial mixer and agitator facilities of the paint industry, the food industry of the pharmaceutical industry.

Available power classes:

285 W – 570 W – 860 W

Stainless steel air motor with integrated holding brake

DEPRAG stainless steel air motors with integrated holding brake are suitable for use in any application area due to their optimal size and design in which safety plays an important role. The integrated brake equipment can be controlled either via a separate control line or directly via the airmotor exhaust. If pressure drops in the line the brake is automatically activated.

The big Plus:

This innovative total package is available with ATEX-certification!

Available in power outputs:

200 W – 300 W – 1.2 kW

Additional information on the ADVANCED LINE air motor

POWER LINE air motors

The POWER LINE air motors range of high-power bracket and flange motors is extremely versatile. The high start-torque at an unmatched low weight, the robust and reliable design are the major advantages of this motor series, when compared to any electric motor.

Your Advantage:

- ATEX certified

- Powerful

- High start-torque

- Low weight

- Robust, reliable design

- Durable

POWER LINE air motor with planetary gear

POWER LINE air motors for high torque with the smallest possible installation size. Available without gear or with precision planetary gear.

Available power classes:

1,6 kW – 3,2 kW – 5 kW

POWER LINE air motor with worm gear

POWER LINE air motors with worm gear are used in applications where self-retention of the gear is required

Available power classes:

1.6 kW – 3.2 kW – 5 kW

Additional information on the POWER LINE air motor

Drilling motor, Milling motor, Grinding motor

Drilling motor:

Our powerful drill spindles feature a slender design that allows for the smallest installation hole pattern in multi-spindle units, as needed in the window- and door industries.

Milling motor:

Our durable milling motors are especially well-suited for robotic applications; they require only minimum installation space but offer a high power-output even at high speeds.

Grinding motor:

Our grinding motors offer the advantages of the reliable, handheld DEPRAG grinders, however in a stationary execution for a direct machine installation. The robust steel housing guarantees high accuracy and operational reliability.

Drilling motor

Drill motors in slim design allow narrow hole spacing in multiple spindle units such as required for window manufacturing.

Available power classes:

from 80 W - 600 W

Speed range:

150 - 24,000 rpm

Your Advantage of the drilling motor:

- Highly accurate drill chuck with taper attachment

Milling motor

The durable milling motors with a superior run-out precision, are the first choice for robotic applications since they are small in size but powerful at a vast speed range.

Available power classes:

400 W

Speed range:

max. 20,000 rpm (according to your individual application)

Your Advantages of the milling motor:

- Robust and precise bearing

- High running precision

Grinding motor

The DEPRAG grinding motor program benefits from decades of experience with the tried and tested DEPRAG handheld pneumatic grinders. The robust steel housing guarantees high accuracy and operational reliability. Furthermore, the grinder spindle feature extremely precise collets for various shaft diameters and offer a high running accuracy.

Available power classes:

from 150 W - 1,000 W

Speed range:

15,300 - 47,000 rpm (according to your individual application)

Your Advantages of the grinding motor:

- Highly accurate collet for different shaft diameters

- High running precision

Additional information on the drilling, milling and grinding motors

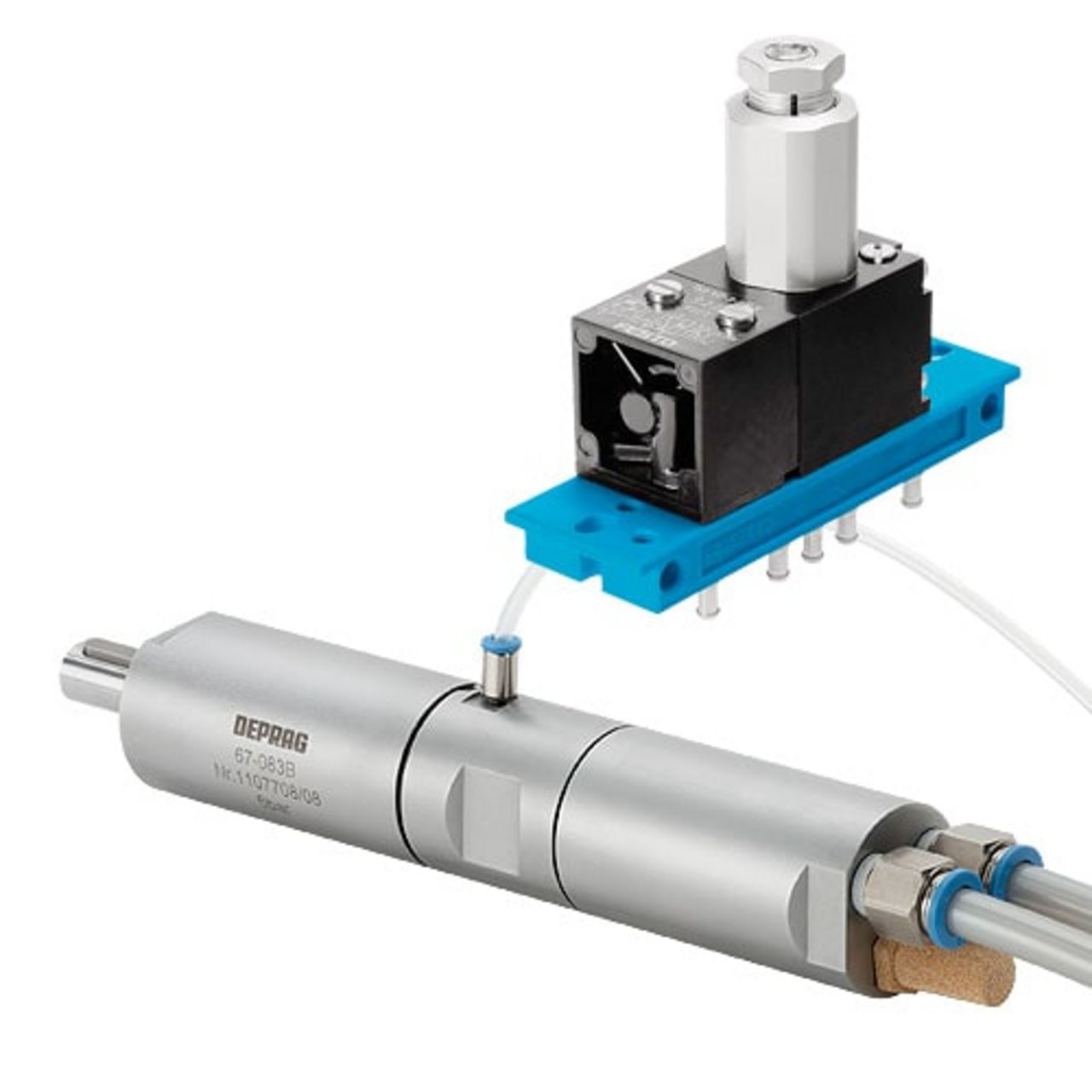

Air motors with integrated holding brake

DEPRAG air motors with integrated holding brake are suitable for use in any application area due to their optimal size and design in which safety plays an important role.

The integrated brake equipment can be controlled either via a separate control line or directly via the air motor exhaust. If pressure drops in the line the brake is automatically activated.

The DEPRAG ADVANCED LINE stainless steel air motors (PDF Product Catalog D 6400) and the 1.6 kW, 2.6 kW and 3.6 kW POWER LINE (PDF Product Catalog D 6600) are available with integrated holding brake.

Your advantages:

- Provide an effective hold of a large mass

- Automatic brake activity when the air pressure drops

- Spindle is held into place without air consumption

The brake is controlled via a separate control line (p > 5 bar) with integrated safety valve.

NEW: The world's first ATEX conform complete system, consisting of air motor, holding brake and planetary gear can be found as a standard product in the ADVANCED LINE pneumatic motor program for 200 W, 300 W and 1.2 kW stainless steel air motors.

Additional information on the air motor with integrated holding brake

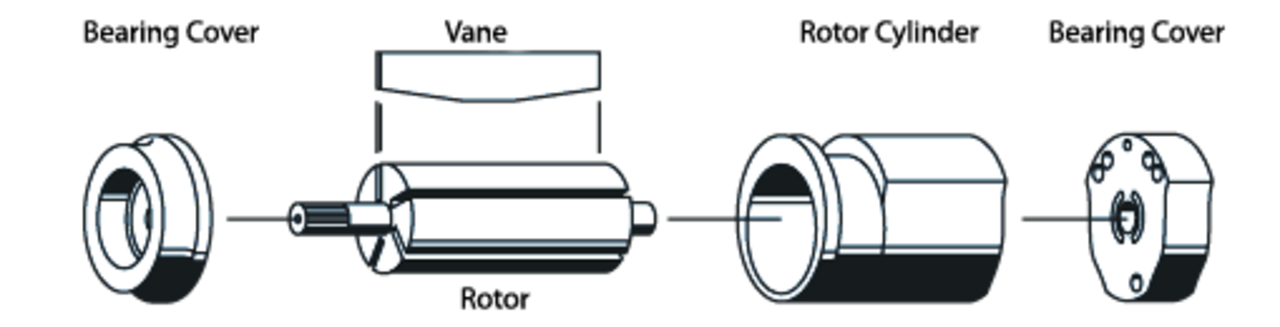

Design and functional principle of a vane motor

Vane motors consist essentially of a rotor which revolves in an eccentrically offset perforation of the rotor cylinder. The vanes form working chambers, the volume of which increases in the turn direction. As the compressed air expands, the pressure energy subsequently transforms into kinetic energy, thereby producing the rotary motion.

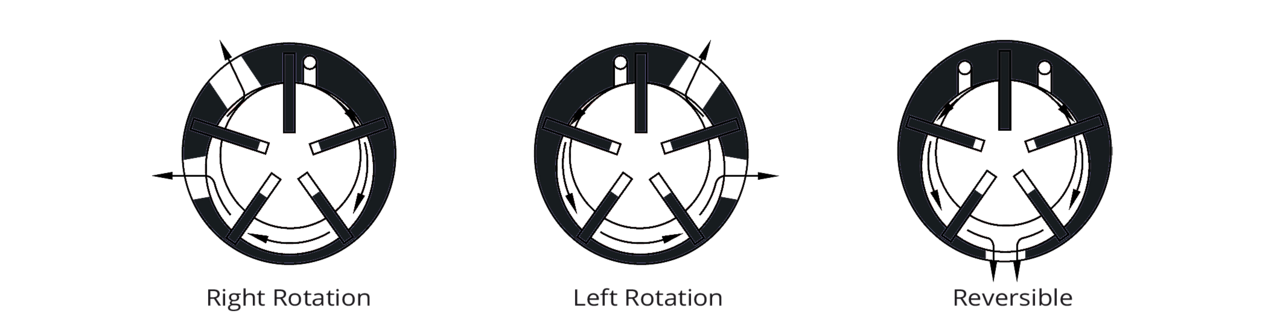

Air motors that are designed to rotate in one direction only, have more rotational angle for the air to relax. Therefore the non-reversible vane motors reach a higher power output and higher speeds than reversible air motors.