Goal of the screwdriving task is either the application of a defined holding strength pre-load force) or the execution of certain adjustment- or dismantling processes.

Application of a defined pre-load force

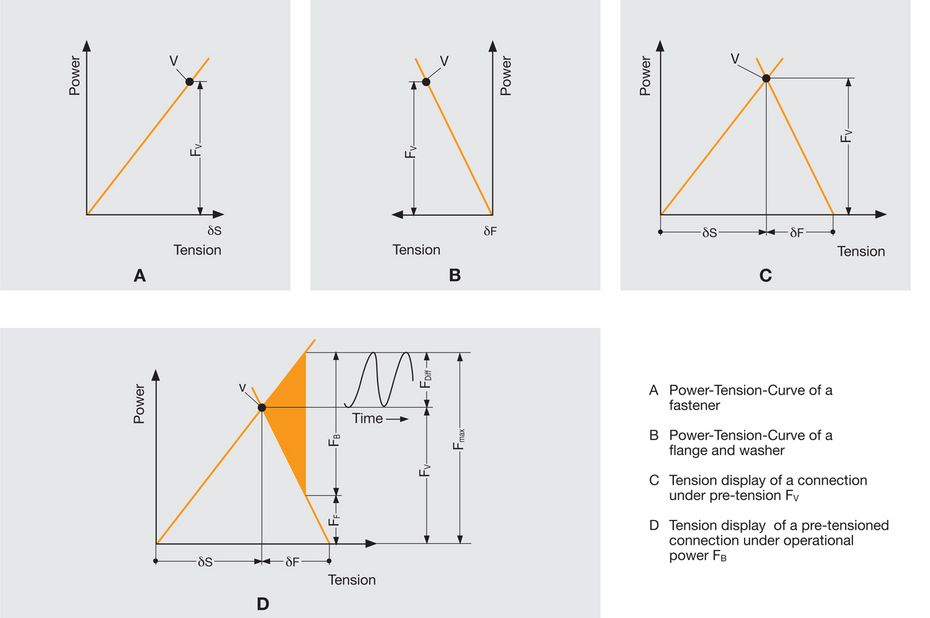

The most important application case in the screwdriving assembly is the determination of a defined pre-load force. The pre-load force has to be determined in such a way, that on one hand the intended function is still a given and on the other hand, the allowable load of the screw-connection.

The most common problems are settling conditions of a joint and other assembly related fluctuations of the achieved pre-load force.

Series screw assembly does not allow effective determination of the required preload force.

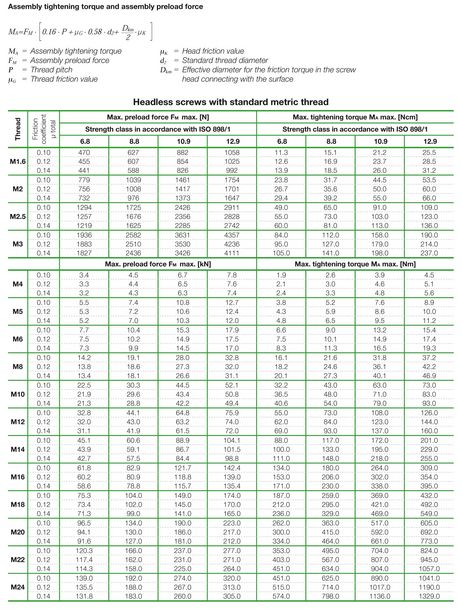

Therefore as an alternative, indirect measurements must be used to control the assembly process. Generally it is the tightening torque of the screw assembly. The required tightening torque can be calculated from the preload force using the VDI 2230 formula.

Additionally other parameters such as angle, screw-in time, friction etc. can be experimentally determined which serve as guide dimensions for the assembly process. Reference values provide us with tables as shown below.

Basically by using the length measurement an additional indirect measurement value can be used to determine the preload force. These processes are however very complicated and therefore not of great use in practice.

Using the torque to determine measurement dimensions is still the best option due to its practical feasibility.

Realisation of adjustment and disassembly procedures

In these cases the described processing dimensions are either a length measurement (screw-in or screw-out depth) or an angle measurement (number of rotations). These dimensions can be recorded directly via a suitable measurement system or indirectly over time.

Example: Assembly of terminal connectors

The clamping screw is firstly tightened to a predefined torque and then unscrewed to a certain angle in order to enable easier connection of a wire.