Screws with a very short shaft, rivets with a wide shaft-diameter and parts with complex external geometries have one thing in common: feeding through a feedhose is often not possible.

Independent from the part geometry

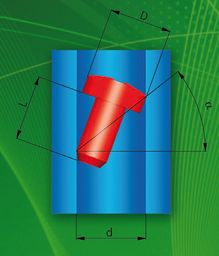

The Pick-and-Place method is an alternate solution, if the feedability criterion a is <30°:

Pick-and-Place Method

For handheld tools, the fastener is picked-up by vacuum suction or by a magnetic bit. The refill signal for the supply of the next component is generated by a pick-up control that is integrated into the cover. After removal of a component, the next component is automatically presented for pick-up.

For stationary applications, a vacuum pickup technology or gripper-handling is used. The pick-up and reloading is controlled by PLC sensor supervision.

Process reliable part-positioning

With the Pick-and-Place method, parts cannot only be directed to the station in true-position, but they are also securely presented to the assembly. A screw is ready for pick-up, with its shaft completely recessed in the bore. The engagement of the bit with the screw drive is simplified, a tumbling of the screw is eliminated and the bit wear is reduced.

Simple start-up procedure

Prior to delivery of your feeder, we carry out an endurance test that simulates your workflow during series production. Each Pick-and-Place device is delivered with a comprehensive documentationthat clearly indicates the start-up procedure and operation of the feeder.