Screws

For the automatic processing of screws, we offer a size-adapted vibratory feeder or a sword (segment) feeder. When starting to automate your assembly process, we recommend our screw presenter.

Here, we can offer standard systems both for handheld as well as stationary applications.

Please use our comprehensive guideline to select the suitable feeding device.

Nuts

For the processing of nuts, we recommend a vibratory feeder.

And, for standardized applications, we can offer handheld as well as stationary standard feed-systems.

Pins

For the processing of pins, we recommend a vibratory feeder.

And, for standardized applications, we can offer handheld feed systems. Stationary applications are often carried out by using an adapted separator.

O-Rings

For the processing of O-rings, we recommend a vibratory feeder.

Our feed-systems can be implemented as part of an assembly solution into stationary machines. The O-ring will be presented into a pickup-position, stretched by an assembly-module and positioned.

Components

We are able to process many different components with our vibratory feeder in combination with a linear-conveyor that sorts and presents the component.

Using an array of sensors allows us to process varying component-geometries in our stationary feed systems.

Small components supplied on reels

The DEPRAG Tape-on-Reel feeder is designed for the delivery of adhesive components (e.g. seals), which are supplied on reel tapes. Those adhesive components can be removed from the pickup location by vacuum or gripper.

This type of feeding system allows the processing of both single-sided and double-sided adhesive components.

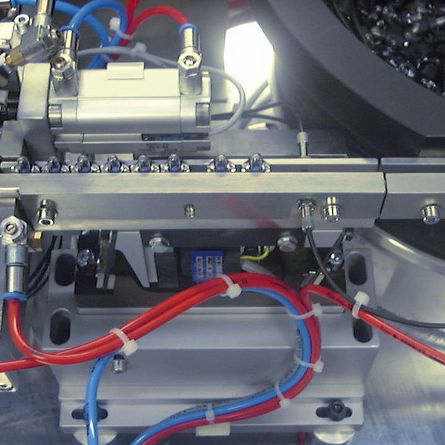

Parts to be press-fitted

For the processing of rivets, pins, sleeves and balls, we can offer our standardized press-insertion systems consisting of a pressurization device connected to either a vibratory feeder or a sword (segment) feeder.

Components that require a gentle handling should be processed by a

Sword (segment) feeder,which is especially suited for its gentle feeding-process, due to its functional operation. Also, vibratory feeder can be coated with a brushed coating or a soft PUR-coating that protects the surface quality of your fastener.

A storage device is able to keep the fill-level of the feeding-system to an absolute minimum, which again serves to protect the surface quality of your components.

If components have to be processed even gentler, then we can palletize them and process them by a gripper- or vacuum handling system. Please contact us for additional information.

Part assembly in cleanrooms

For the processing of components in cleanrooms class D, a vibratory feeder in connection with a suction device, can be used.

If your cleanroom requirement is even higher, then a palletized solution with gripper- or vacuum handling can be used.