In particular with the handling of small, sensitive components, the subject of Technical Cleanliness is becoming more in demand, for example in the manufacturing of light electronic or hydraulic products. In response to the rising trend of Technical Cleanliness we now offer a program of specifically designed solutions.

The assembly of critical parts, components and systems in conjunction with Technical Cleanliness is done in the so-called clean production environment. DEPRAG offers proven components that meet the requirements of Technical Cleanliness in automatic parts feeding and assembly. Particles are minimised using friction and/or vacuum with the help of a range of methods and components.

Particle Killer and BitCleaner – The components for technical cleanliness

For the installation of critical parts, components and systems for the purpose of Technical Cleanliness produced in the context of so-called "Clean Manufacturing". DEPRAG offers a cost-effective, technically advanced solution that meets the requirements of Technical Cleanliness for automatic part feeding. Contaminants are collected and extracted in process using vacuum.

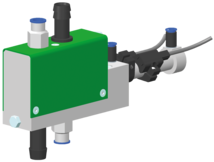

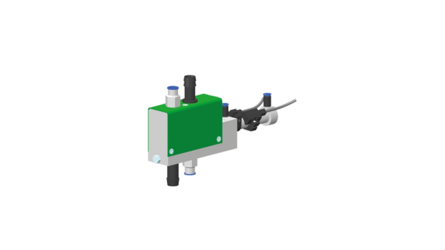

The DEPRAG Particle Killer Inline version is ideally attached directly to the screwdriving system. In this way, any contamination transported from the feeding process and feed hose is already removed prior to the start of the screwdriving process. Furthermore, any dirt particles which are generated from the air shot process (e.g. when the screw is decelerating) can be removed and caught by a filter. This procedure optimises the Technical Cleanliness in the production process.

The DEPRAG Particle Killer Pick&Place version is used when a screw is fed via feed hose but is positioned in the component using the P&P procedure, for example when using the Tool Changer concept. Many different types of screws can be processed using the Pick& Place version.

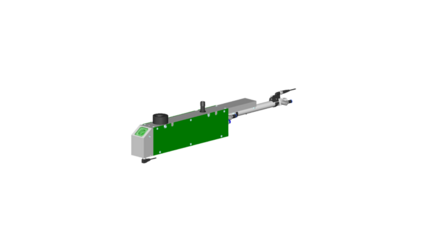

The DEPRAG BitCleaner is the latest feature in DEPRAG’s CleanFeed concept. This involves the removal of metallic abrasion created during the engagement process (connection of the bit with the screw drive) which becomes adhered to the bit. Cyclical cleaning (e.g. 2x per shift, depending on the screw coating, screw drive, ...) significantly improves the Technical Cleanliness of the process.

Technical Information

Available components of the Concept for Technical Cleanliness

The component is stopped at position 1 and particulates on the auto fed part (e.g. screw) are extracted via vacuum. The particulates are collected by an exchangeable filter element (which is visible through a viewing pane).

In position 2 the cleaned component is presented either to the auto assembly module tooling (Inline Variant) or to a pick position (Pick&Place Variant).

Application of the following equipment can help to produce the optimal results:

- Pre-cleaned assembly components (e.g. Arnold Cleancon® screws) ► Fewer particulates due to an additional cleaning process

- DEPRAG HSF Sword Feeder ► Vibration free part feeding and therefore less particle generation

- DEPRAG Particle Killer ► Debris in the autofeed process is reduces selectively

- DEPRAG BitCleaner ► Metallic abrasion is extracted

- DEPRAG SFM-V vacuum screwdriving module ► Debris created during the assembly process is extracted usin vacuum sources

Additional information about the Components for Technical Cleanliness

Contact our engineers here if you have any questions about our products. We will be happy to provide you with an individual offer.

Download product catalogue now

More information about the Concept for Technical Cleanliness (D3820) can be found here.

In the training Feeding Technology, you will acquire in-depth knowledge of the feeding equipment you are using.