This adaptive screwdriving procedure ensures a constant clamp force when drive-in torque values are fluctuating. The whole screw assembly consists of the head contact recognition and a screw assembly to differential torque or to a specific angle.

Typical area of application is direct screwdriving into plastic and/or metal. The patented screwdriving procedure for DEPRAG EC servo screwdrivers in combination with the AST12 or AST40 is used for greatly varying tightening torques.

These fluctuations may result from alterations in the geometry of the screws and/or hole, the component’s material structure, variations in surface quality of the screw thread, elasticity of elements or seating processes. The reliable recognition of head contact results in a constant clamp force.

Advantages:

- Improved constancy of the pre-load force

- Calculation takes into account coincidental fluctuations in the torque during

the process, which are not caused by head contact - Minimal parameter adjustments

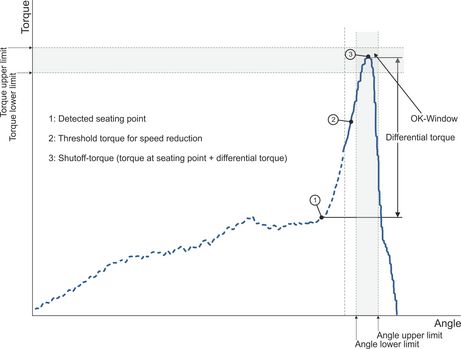

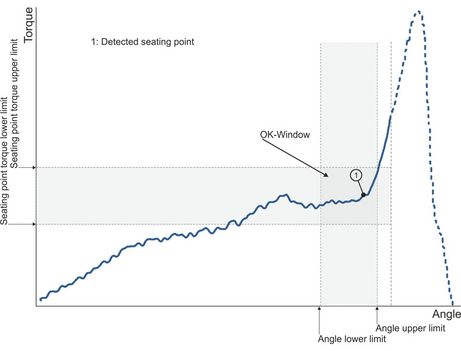

Method of calculation:

The main element is the head contact recognition: based on the torque flow, a mathematical valuation function is continually generated. Head contact is deemed to be recognized as soon as this function exceeds a fixed limit value. Torque and

angle are calculated backwards to the moment of head contact.

The torque upper limit serves as the shut-off criteria for the screwdriving step. The OK window for seating recognition can optionally be monitored using the seating point torque upper/lower limit. The end values can either be saved as the torque and angle values at the point of seating or the end of the screwdriving step. The end values of the screwdriving template seating recognition provide the reference for the following program section.