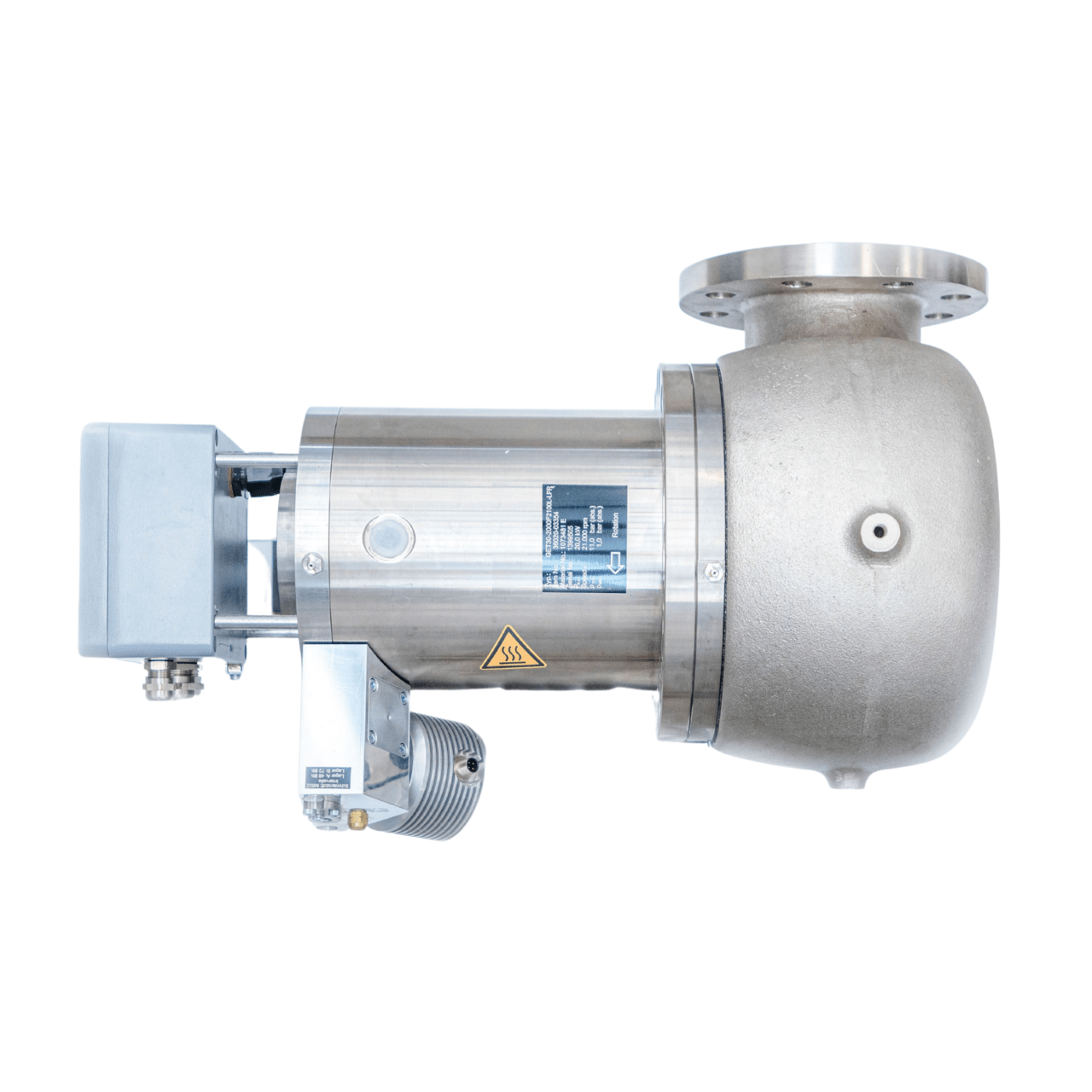

With our turbines we offer energy-efficient, continuous operating, high-speed drives that guarantees low air consumption with an optimal power to weight ratio. Click hear to learn more about the functionality of a turbine motor.

The turbine is customised for your specific application

- Mass flow or desired power output

- Inlet/outlet pressure

- Medium (type of gas)

- Speed, turn-direction

- Inlet temperature

- Mounting preference

- Material request

fluid mechanically designed and calculated, constructed and customised.

You would like advice on our turbine or have further questions? You need a concrete offer for your project? Our experts will be happy to advise you. Get in touch today.

Please use our inquiry form for turbine motors.

Energy recovery application of a turbine

Our turbines generate electricity even from small amounts of process gases.

With a low investment outlay, you can convert your existing residual energy into electricity and thus significantly reduce your commercial electricity consumption. Click below to find out more about the turbine generator.

Using a turbine for an aircraft emergency door

The pyrotechnic ignited, indirect turbine drive with reduction gearing is used for the PYROTAK emergency door system. This system offers a high power-output by a very small-sized turbine.

Use case 1: turbine grinder application

Use of a high-speed turbine in a turbine grinder

- Power = 250 W

- Free Speed = 70,000 1/min

Use case 2: turbine grinding machine

A two-stage curtis turbine is used for this turbine grinder. When compared to multi-stage overpressure turbines, this grinder has a simple layout and is especially cost effective. The deciding advantage for this application is the extreme low weight.

- Power = 2.2 kW

- Free Speed= 12,200 1/min

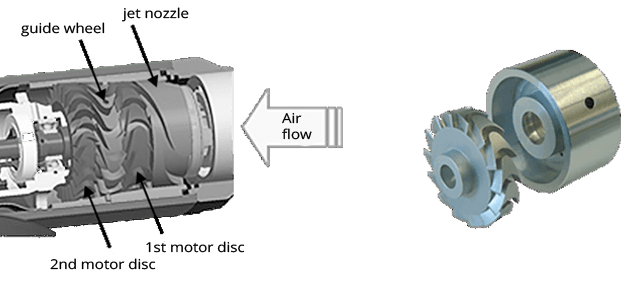

Design and functionality of a turbine motor

Pneumatic turbines are continuous-flow machines, which can be executed in single-stage or dual-stage design.

The conversion of the pressure energy into kinetic energy takes place in the inlet nozzle. On a two-stage turbine, the largest part of the kinetic energy is converted in the 1st turbine wheel. The air-flow is diverted over the stationary turbine wheel. The remaining energy is converted in the 2nd turbine wheel.

The turbine does not require any contact seals. Therefore, the operation of the turbine with non-lubricated compressed-air is totally free from wear. Continuous-flow machines optimally utilize the energy of the compressed air. Therefore, the air requirement of a turbine motor is 1/3rd less when compared to an pneumatic vane motor. The power to weight ratio [kg/kW] is only half.