For handheld applications, you find in our standard product line equipment, starting with our screw-presenters for the manual pickup of a screw, as well as our feeders that are designed to supply one or two workstations with screws that are automatically presented to handheld screwdrivers.

For the automatic transporting of fasteners, vibratory-, sword (segment)- or Pick-and-Place equipment is available.

Press-Insertion systems for pins or rivets round off our extensive product assortment.

DEPRAG screw feeding systems consist of:

- the feeder

- the handheld screwdriver or press-insertion tool

- a maintenance unit

- an electronic control

The feed-system also contains tooling, such as a nosepiece ball-type or split-type, which is adapted to fit your fastener and application. The feeder also includes the mouthpiece-guide and a set of.

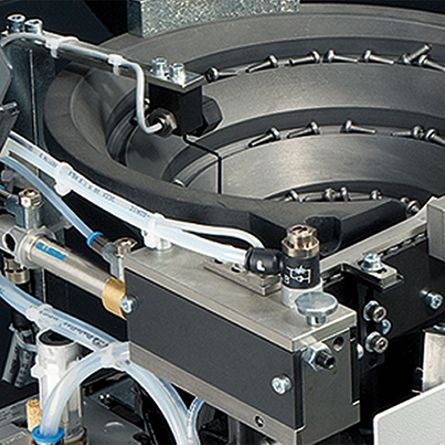

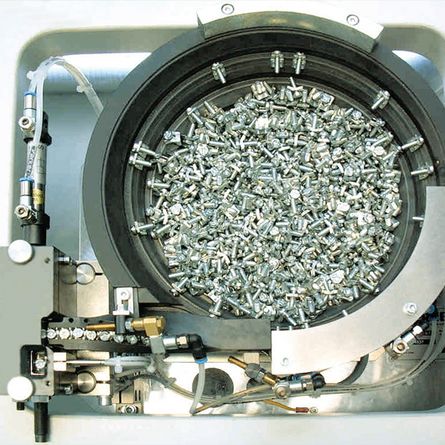

Vibratory Feeder eacy feed

For manual assembly applications, eacy feed offers flexible and efficient solutions along with top quality DEPRAG screwdrivers.

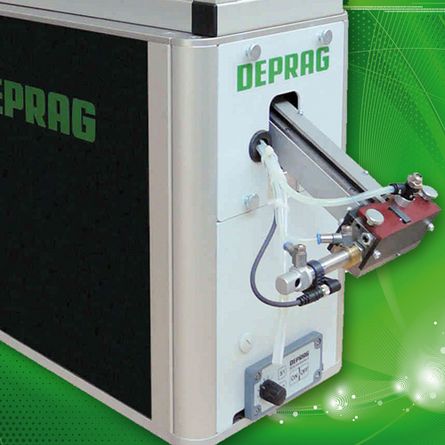

Sword (Segment) Feeder

in sizes with 0.15 l and 1.5 l – fill volume

Sword seeders or segment feeders are used when the requirement calls for the gentle and nearly noisless feeding of sensitive fasteners.

Mini Screw Feeder

The DEPRAG Mini Screw Feeder is perfectly suited for feeding very small rotationally symmetrical parts such as micro and mini screws.

By means of a rotating disk, one fastener at a time is brought into a defined position and made available for picking. Picking can be performed via magnet or vacuum.

Step feeder system eacy step feed

The complete system, comprising a storage container, material-handling technology, linear conveyor, separator, housing and controller – specially designed for longer screws – offers hassle-free, reliable operation with 24V technology, independent from mains voltage and mains frequency.

DEPRAG Feed Module – DFM

The DEPRAG Feed Module (DFM) enables screw assemblies on screw positions which are difficult to access, by using vacuum assistance.

Pick-and-Place Feeding

If the screw dimensions do not allow feeding through a feedhose, for example where there is an unfavorable relation between screw head diameter and overall length, we can offer special solutions, such as the Pick-and-Place process with vacuum suction or removal by gripper. This process can also be used if there are screw-locations that are difficult to access.

Screw Presenter and Screw Dispenser

Screw presenters are mainly used for applications where an automatic screwfeeding machine is not cost-effective due to low volume.

Screw dispensers are optimised for the reliable supply of screws at manual workstations.

Storage Devices

We offer an assortment of storage devices that are the ideal addition to our feeding systems. Belt-driven hoppers dramatically increase the required refill intervals. Our hoppers are flexible devices that can be used for different parts – a costly refitting is not necessary.

Press-Insertion Systems Handheld

Pressurization systems consist of coordinated modules: the handheld pressurization device and the automatic feeder for the fasteners, such as rivets, pins and sleeves.

The efficient and process reliable pressurization and placement operations are done by hand.