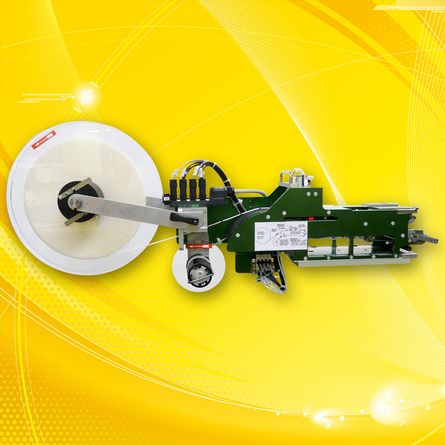

The DEPRAG Tape-on-Reel Feeder is specifically designed for the process-reliable and position-accurate delivery of adhesive components, which are supplied on reel tapes. This type of feeding system enables the assembly automation of both single-sided and double-sided adhesive components, which are frequently used as a sealant.

Function

Tape-on-Reel feeders are loaded with a reel, which is placed onto a reel-reception. The peel-off carriage pulls the reel tape forward, until the next component is in the pick-up position. As soon as a sensor has indicated that a component is at the pick-up position, a downholder moves down and locks-down the tape. As soon as the part-handling (such as a vacuum gripper) signals ready, the slide moves back to expose the cutter-edge and the reel-tape is rolled up by a wrapping-device. The component is loosened from the reel-tape and is ready to be processed by your part-handling feature. After the part-handling (such as a vacuum gripper) signals ready, the slide moves back to expose the cutter-edge and the reel-tape is rolled up by a wrapping-device.

Position-accurate delivery

By using a combination of highly precise sensors and a rapid tape-locking device, our tape-on-reel feeders can achieve the position-accurate delivery of components with a repeatability.

Robust und reliable

The use of resistant materials during the manufacturing of our Tape-on-Reel feeders assures a consistent high quality, extended up-time and efficiency of those feeders when used in an industrial mass-production environment.

User-friendly functionality

The simple adjustment of the detach-position in height and X-axis, the quick unlock-feature of the roller-drives, a tape presence control, as well as the easy access to all important components, are key features of the DEPRAG tape-on-reel feeders. When using this feeding system in connection with a single- or multi-axis DEPRAG DCAM (DEPRAG compact assembly module), an extremely efficient and compactly designed turnkey system emerges for the placement of components.

Solutions tailored to customer specific requirements

If you wish to integrate a tape-on-reel feed-system directly into your assembly machine and if restrictive space conditions have to be considered, then we will adapt our standard devices to fit your installation conditions. You profit from our unique know-how and moreover, you receive a mature and fully-tested feeding system at an especially attractive price-to-performance ratio.

When ordering a customer-specific device, you will naturally receive the necessary 3D-data to facilitate an easy integration into your system.

Simplified start-up

Prior to delivery of your tape-on-reel feeder, we carry out an endurance test that simulates your workflow during series production. Each device is delivered with comprehensive documentationthat clearly indicates the start-up procedure and operation of the tape-on-reel device.

Additional Information:

Tape-on-Reel Feeders:PDF Product Catalog D 3870