Screwdrivers

Our comprehensive product line includes screwdrivers

- for a manual application or the use in stationary equipment

- with electronic or pneumatic drive

- with a torque range from 8 Nmm (1.14 inch ounces) to 500 Nm (4,425 inch pounds

- with various design executions to accommodate different application scenarios

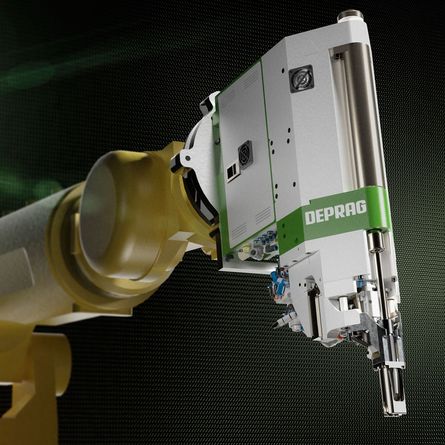

Screwdriving system DEPRAG Plus

Connectivity, user-friendliness, flexibility, efficiency and documentation capabilities: these key characteristics are decisive factors in choosing a screwdriving system. These features were all vitally significant in the development of the new generation – a platform for the digital future.

Control Technology

To assure the safety of your production process the

- sequence controllers AST5-S, AST12 and AST40 not only supervise the screwdriving process, but also control and monitor data for central data collection and retrieval, compare data with external databases and allow the worldwide access to the processing data

- screwdriver function controls fc11 and fc20 can supervise a complex assembly process by using programmable sequences

Feeding Technology

Automatic feeding of fasteners

- for a manual application or the use in stationary equipment

- for standardized sizes of fasteners from M1 to M16

- single, double or multiple feeding

- vibratory, sword (segment) or tape-on-reel systems

- transport through a feedhose or by pick-and-place procedure

Measuring Technology

To assure the safety of your production process, we offer a wide range of torque and angle measurement instruments that are suitable for many different tasks:

- analyze your individual screw-joint

- verify your torque/angle values

- supervise your assembly process

- document your screwdriving results

- supervise, adjust and counter-measure your screwdrivers

- calibration service at the DEPRAG DAkkS calibration laboratory

ADAPTIVE DFS

The adaptive assembly unit ADAPTIVE DFS combines EC-Servo screwdriving technology with EC-Servo stroke technology:

- Highest process reliability

- Shortest possible cycle time

- Optimized funnel forming

- Avoids thread damages

- Less stress on fastener and product

- Reduces set-up time

- Designed for new materials, fasteners and joining methods

Accessories

A comprehensive line of accessories completes our product program

- assembly components for system integrators

- set-up components for your manual workstation

- ergonomic, process-reliable guidance of screwdriving tools by sturdy screwdriver stands

- insertion tools of all kinds, such as bits and sockets

Individual Solutions

We offer customized, economic solutions that are perfectly adapted to fit your application.